TPU is a flexible material widely used in many industries including automobile, electronics appliance, and variety of cable, tube and adhesive coating. With the powerful addition of 3D printing, lots of new applications becomes possible using TPU because of its excellence properties, for example: high elasticity, high strength, transparency and etc.

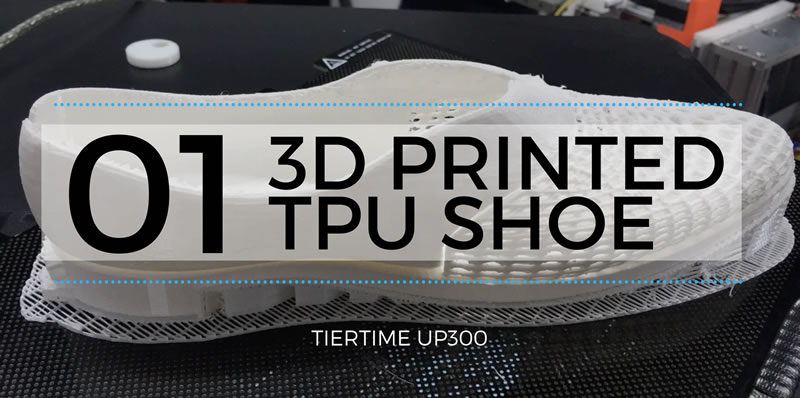

Today, we would like to use our newly launched UP300 to print a shoe. Yes, a whole shoe. Tiertime UP300 3D Printer added the TPU support in its arsenal, and came out with a dedicated TPU extruder. If you are into the 3D printing for a while, you may know that TPU filament is flexible, meaning it is soft, compared with ABS or PLA, the hard filament. It will be hard to feed the TPU filament into the extruder if you want the extruder to support both hard and soft filament.

The TPU extruder has a different design which makes TPU feeding easier. Along with new glass bed in UP300, it can print raftless models with flat bottom.

Let’s see how UP300 prints the shoe:

It took 17 hours, 300 grams of TPU filament to print the shoe:

Our customer in shoe business really likes the 3D printing solution that Tiertime provided, because it is a “paradigm shift”. With the 3D printing, plus the acceptable polymer, it can totally change their workflow, or even the way they design the shoe.

If you would like to know more about UP300, please contact us for detail, or talk to our local partner for more information.